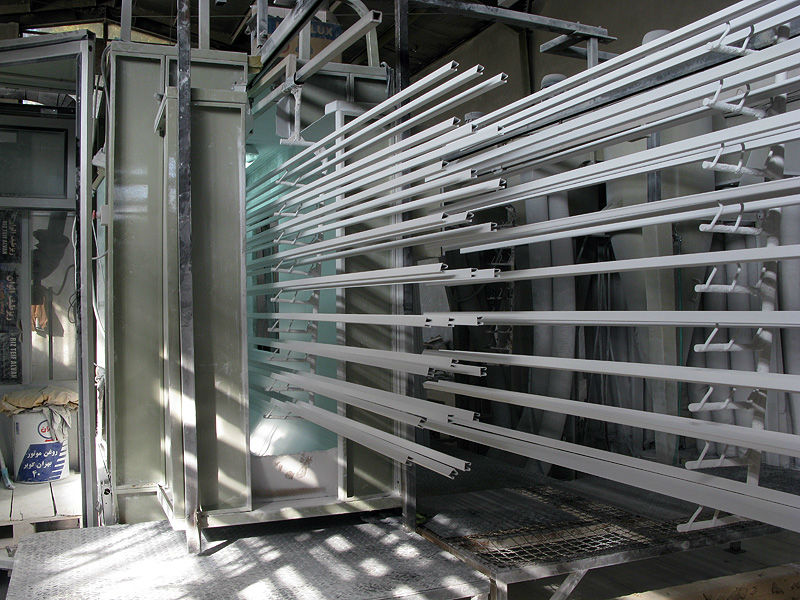

POWDER COATING SURFACE FINISH LINE

WHAT YOU WILL BE REQUIRED?

Aluminium extrusion powder coating line main parts Like Pretreatment, water drying oven, powder curing oven, gas direct heat exchange, suspension conveyor machine, electric control system, powder room, powder spraying equipment and so on

Powder Painting Room

Powder Coating Process:

Loading→powder spraying→ powder curing 180-220℃(15-20minutes) →cooling and unloading

Curing Oven

Drying Oven

Technical Parameters Of Powder Coating Machine:

Production Line: Horizontal/Vertical

convey speed: 2m/min

maximum profile size: L7000*W250mm*H1800mm

working temperature: around 230 degrees

fuel: gas or oil

curing time:18~20min

heating capacity: 400000kcal

heat up time: 40min

temperature test: 2 points

painting method: manual and automatic

Painting room material: PP plate

powder recycle ratio:99%

Powder Coating Line Main Parts